Russian chemists studied how the position of a reaction vessel above a magnetic stirrer affects the course of heterogeneous reactions. They found that the formation of palladium nanoparticles and the Suzuki reaction proceed at different rates and yields depending on how far the reaction vessel is from the center of the stirrer. This could lead to the publication of non-reproducible results, the authors warn in the journal JACS Au.

In the laboratory, reaction mixtures are typically stirred using magnetic stirrers. The chemist inserts a magnetic stirrer, typically cylindrical, into a flask or other reaction vessel, then secures the flask in a stand above the magnetic stirrer. The stirrer's rotation speed can be adjusted, and then stirring is activated. The stirrer begins to rotate, stirring the reaction mixture.

It's well known that stirring plays a crucial role in reactions involving large amounts of starting reagents, and poor stirring can prevent the reaction from proceeding at all or lead to different products. However, it's generally accepted that for small vessels of a few milliliters, which chemists typically use in experiments, the effects of stirring are less important.

Chemists led by Valentin P. Ananikov from the Zelinsky Institute of Organic Chemistry of the Russian Academy of Sciences raised doubts about this. During their work, they noticed that some heterogeneous reactions were difficult to reproduce and decided to investigate the causes of this phenomenon. As it turned out, in some cases, this was due specifically to the stirring of the reaction mixture.

To demonstrate how small differences in mixing affect the reaction, chemists 3D-printed a rack for small jars with screw-on lids. The rack had three height levels, each accommodating five jars. The chemists then placed 15 jars containing a palladium complex and carbon nanotubes in the rack and observed how the palladium deposition reaction on the nanotubes proceeded depending on the jar's position. It turned out that not only did the reaction rates vary from jar to jar, but so did the size distribution of the resulting palladium nanoparticles. For example, in one jar in the second row, particles of four nanometers in size predominated, while in one jar in the third row, particles of about one nanometer in size predominated. The chemists observed similar differences in the formation of palladium nanoparticles without nanotubes.

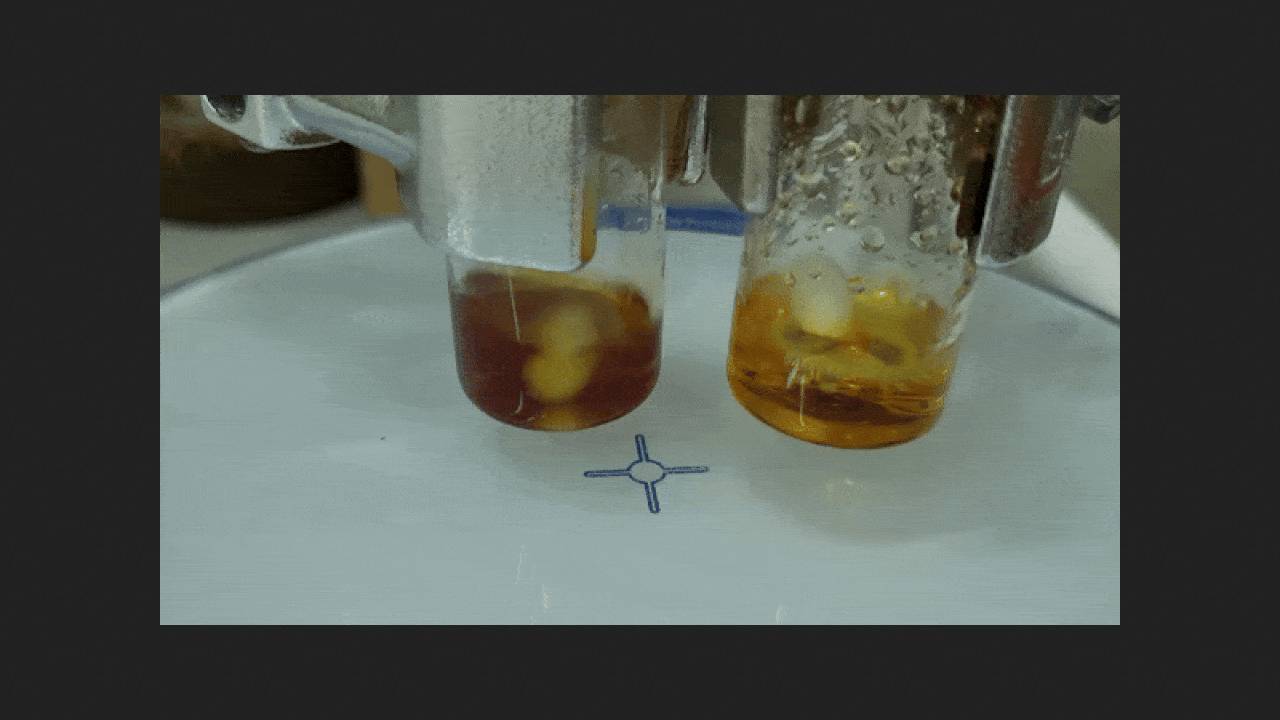

The scientists then investigated how the position of the vessel above the stirrer affected the conversion of the Suzuki reaction catalyzed by commercial palladium-on-carbon. In this case, nine reaction mixtures were positioned at the same height but at different positions relative to the center of the stirrer. As a result, the average conversion of the starting material at the center of the stirrer was approximately 45 percent, while at the outermost position, it was approximately 26 percent.

Thus, for some reactions, small differences in stirring can lead to large differences in results. As the scientists have shown, reactions often proceed faster and with better yields when the reaction vessel is positioned as close to the center of the stirrer as possible. This is precisely how the authors of the article advise other chemists to conduct chemical reactions. They also recommend that the experimental section of chemistry publications should include the parameters of the magnetic stirrer and magnetic anchor, as well as a photo of the reaction mixture.

The results of chemical experiments can be affected by very small differences in the purity of the starting materials, the reaction vessel, and the magnetic anchor. We discussed in more detail how this makes studying catalytic reactions difficult in our article "The Dark Side of Catalysis."