Chemists from France have learned to convert silicone polymers into monomeric chlorosilanes. They used boron chloride as a chlorine source and gallium chloride as a catalyst. As the researchers report in Science, they succeeded in depolymerizing silicone oils, baking molds, and recycled silicone-containing waste.

The chemical industry produces over two and a half million tons of silicone polymers annually. To do this, chemists take natural quartz (SiO2) and extract elemental silicon (Si). This silicon is then introduced into the Müller-Rochow process, where it is heated with methyl chloride (CH3Cl) to 300 degrees Celsius in the presence of a copper catalyst. The resulting mixture is chlorosilanes (CH3)nSiClm. The mixture is separated, and its components are used to produce silicone polymers.

Silicone polymers are used to produce sealants, pipes, oils and lubricants, cosmetics, various rubber products, and much more. At the end of their life, these products either end up in landfills or incinerated. Scientists have yet to develop an effective way to recycle silicones.

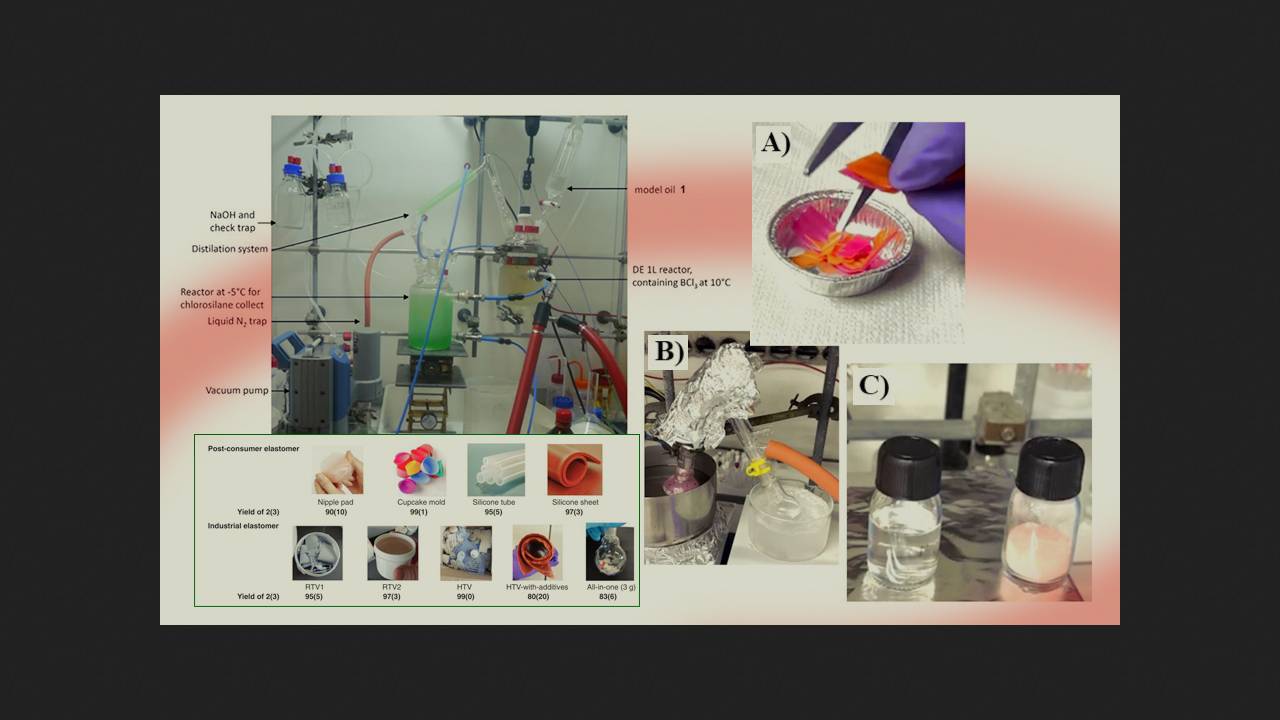

Recently, however, chemists led by Jean Raynaud from the first Claude Bernard University in Lyon have proposed a convenient method for depolymerizing silicones. They used a combination of two Lewis acids—boron chloride BCl3 and gallium chloride GaCl3—to convert silicones into dimethylchlorosilane (CH3)2SiCl2.

The researchers first tested this reagent combination on silicone oil. They mixed it with an excess of BCl3 and a catalytic amount of GaCl3 in toluene. After two hours of heating at 40 degrees Celsius, the scientists isolated dimethylchlorosilane from the reaction mixture in 95 percent yield, and the boron chloride was converted to B2O3. However, the reaction did not work if the chemists used either BCl3 or GaCl3 alone, rather than a combination of the two.

The method was then tested on commercial silicone samples. Both for silicone oils with varying degrees of polymerization and for more complex rubber products—breast pads, baking molds, silicone tubing, and sheets—the yield of dimethyldichlorosilane exceeded 90 percent.

Thus, chemists have developed a method for producing the main precursor of siloxane polymers—dimethylchlorosilane—from the polymers themselves. This method may help conserve natural quartz reserves and reduce the energy consumption of the Müller-Rochow process.

We recently reported on how chemists learned to recycle Teflon and plexiglass.